Material

At present, the common vacuum packaging bag materials are generally selected: PA+PE, PET+PE, MOPE, PVC, etc. Now the best material should be nylon+polyethylene (PA+PE).

The vacuum compression bag of PA+PE is made of a new type of plastic compounded by nylon and plastic. This material is the premise to ensure no air leakage. It has good flexibility and durability. It does not change its properties when exposed to low temperatures, but the cost is relatively high. PA+PE can burn slowly during the combustion test, the flame is bright, the bottom is blue, the top is yellow, and it continues to burn after melting and dripping, no smoke, with the smell of candles blowing out and burning wool.

The other is PET+PE material. PET is commonly known as polyester polyester. The vacuum compression bag made of PET+PE is not soft enough, especially it becomes hard and easy to break at low temperature.

So how to identify these two different materials?

To identify two different materials, it is best to compare them side by side. The method is: first, touch, the softer hand is made of PA material, and the harder one is made of PET. Second listen, rub it with your hands, the duller sound is made of PA material, and the sharper sound is made of PET material. The third is to put the two materials in the refrigerator for a while, and the harder one is PET.

The advantage of MOPE is that it is very soft and feels better than others, but the adhesion is not good, and there are generally more air leaks.

Needless to say, PVC is not environmentally friendly. PVC is non-flammable, and extinguishes immediately after leaving the fire. When burning, it appears yellow-orange, with green edges, white smoke, and light green and yellow flames. It softens, can be drawn, and has a pungent hydrogen chloride odor.

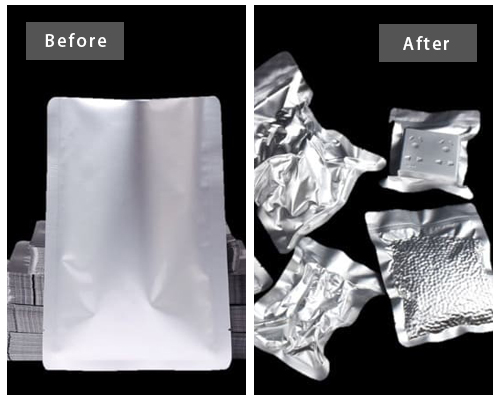

thickness

The thickness of the vacuum compression bag is represented by “silk”. Generally, the thickness of the vacuum compression bag is 6-8 threads. The larger the number of “silks”, the thicker the bag. Generally, it is better to use vacuum compression bags with 6-8 wires, because such bags are of moderate thickness, and the bags will not be too hard and brittle because they are too thick. It will not be scrapped in a year or two because the bag is too thin. Generally, 6-8 silk PA+PE bags can be used for about 5 years.

There is also a look at the details, a good vacuum compression bag must be more precise in the exhaust valve and seal and even the zipper slider. Good quality always runs through. If you encounter those unscrupulous merchants in the future, if you still can’t tell the truth from the fake, then you should contact us, and Honest’s customer service will do their best to help you fight fakes!