Sales Questions

For certain unprinted pouches, 5000 pcs is the minimum quantity you can order. Normally we need 10000-20000pcs for printed pouch, very small bags will need 50000pcs for a start. Now we offer digital print options, it can start from 100 pcs customize printed pouches.

Before we print your pouches, we will send you a marked and color separate artwork proof with our signature and chops for your approval. After that, you will have to send a PO before the printing starts. You can request printing proof or finished products samples before mass production start.

Yes, we recommend that you try our pouches before you purchase them. This ensures that you get the right color, size and the design you desire. You can request both our exist samples or custom samples, custom samples may need charges.

We accept Adobe Illustrator, PSD or PDF. You can save the PDF from your set up and send us the artwork in PDF format. The size and the printed content on the front and back are clearly marked. The text is best to be converted into paths and the image is clear. We will adjust it according to the bag making requirements and submit it to you for confirmation.

Our company provides a wide range of custom laminating materials which can meet our clients’ diverse needs. Some of them are Matt-BOPP, BOPP, AL, PA, VMPTE(PETAL), Matt-PET, PET, PP, PE, LLPDE, Milk White PE, CPP, VMCPP(PETAL) and many others.

The complete information required for the quotation includes the bag type, size & specifications, printed pattern, quantity, functional requirements, etc. If these are not known, the most basic you need to tell it is what is used for packaging, how much is packaged, we can also give you the appropriate Suggest.

We start production as soon as your design is confirmed, we have multiple factories that can arrange your design for printing production.

We offer flexo, gravure, offset and digital printing, supporting up to 12-color printing effects, as well as laser, hot stamping, and more.

No! We specialize in oversized productions! So, if you are looking for oversized packages to display at your tradeshow, floor displays or even posters we can help! We have multiple printers that can produce large-scale printing.

All the images in Honest are flexible unless credited otherwise. All the printing rights are reserved.

Our clients reserve the rights to make any changes regarding specifications, drawings, packaging, quantitative, specifications, methods of shipment or even the delivery schedule as to the goods ordered.

Before the official confirmation of the order to start production, you can modify the file repeatedly until you are satisfied. We will provide the typesetting file to confirm the text content, size, pattern, heat sealing and diecut requirements. Once confirmed and begin to make the packaging, the price difference or time difference in performance resulting from the changes will be equitably adjusted as well as confirmed in an agreement.

These types of polyethylene (PE) sheeting are lightweight and should be selected based on the strength and durability needed:

- Most common: Use (Low Density Polyethylene) for applications needing softer, more malleable, plastic sheeting. LDPE is not recommended if heat or puncture resistance are needed.

- Most versatile: Chose LLDPE (Linear Low Density Polyethylene) for the most flexibility in use. It’s soft and pliable like HDPE, yet is stronger and more durable.

- Strongest: Use HDPE (High Density Polyethylene) for applications needing denser, more rigid, stronger plastic sheeting. Its molecular composition means HDPE can withstand higher temperatures than LDPE or LLDPE.

Our company accepts normally PayPal, T/T, and L/C payments. Call or email us if you need to use any new payment procedures.

- We require payment before goods are shipped.

We accept all major US credit cards including MasterCard, Visa, Discover and American Express.

Yes. We still run custom sizes as specialized projects for each customer.

Yes. We are fully capable of custom laminating materials to meet our customers’ specifications.

Yes, we can! We have a complete in-house graphics department that can assist you with your artwork or design questions. Artwork design or modification services are available for a minimal fee.

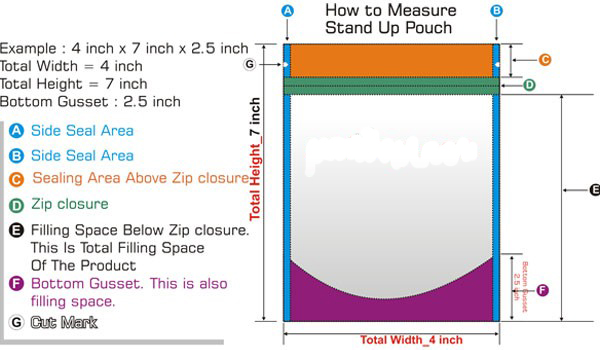

Packaging Bags & Pouches & Shrink Sleeve Label

We highly recommend that you use aluminum foil materials for such purposes. However, we also give metalized films which work well with extreme sunlight. To protect your product from moisture, you can also use other materials such as polypropylene and nylon. Some coatings on our pouches come with the best moisture barrier.

1 mil – Used for dust protection; small parts, stationery, and box liners.

1.5 mil – Used for moisture protection; manuals, clothing, nuts, candy, other food items, and box liners.

2 mil – Used for protecting parts, supplies, lightweight, items, clothing, food, and box liners.

3 mil – Used for medium weight items; hardware, electrical, and plumbing supplies; mattress covers.

4 mil – Used for bulky items or items requiring added strength; bolts, screws, and industrial parts.

5 mil – Used for items that require heavy-duty protection; hardware, construction waste, sharp-edged objects.

6 mil – Used for items requiring extra heavy-duty protection; sharp-edged objects and industrial parts.

8 mil – Used for heavier; bulkier items requiring maximum strength bag; industrial parts, gears, and heavy metal objects.

Flat Poly Bags

Width (W) x Length (L)

Bag widths under

18″ do not include

bottom tail in length measurement. Sizes

18″ & over include bottom tail.

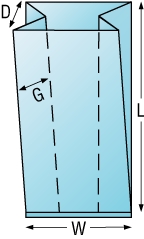

Side Gusseted Bags

Width (W) x Depth (D) x Length (L)

Depth = Gusset (G) x 2

A gusset is a triangle shaped fold on either side of a bag. The gusset is considered the depth of a bag.

Bag widths under 18″ do not include bottom tail in length measurement.

Sizes 18″ & over include bottom tail.

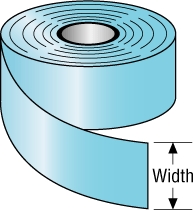

Layflat Tubing

Layflat Width = 1.57 x Diameter of Object (round up to next size)

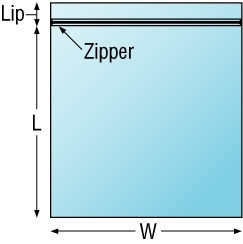

Zipper Bags

Width (W) x Length (L)

Zipper bag measurement does not include the zipper and lip.

There are a large number of alterations that can be made to a bag to ensure that it precisely matches your application. These changes can be made individually, or in combination, depending on your needs. The list below contains many, but not all, of the custom options we have to offer you. And if you don’t see the particular option you are looking for, please call our custom product experts.

Vent Hole – A small hole is added to the bag to allow air and moisture to pass through the bag

Hang Hole – A hole is added to the bag, usually near the top, allowing it to hang on a hook or have a tie inserted

Grommet – A hang hole reinforced with a metal ring to help keep the bag from tearing

Flap Lock – A lip folded back and sealed on the sides, allowing it to be flipped over to lock in the contents of the bag

Lip – Making one side of the bag longer at the opening, allowing the bag to be closed by folding over the longer side…can be used with a glue strip

Glue Strip – A line of adhesive added to the bag to make it self-sealing…can be permanent or resealable

Imprinting – Adding words and/or graphics in one or more colors to the bag

White Block – A white area imprinted on the bag allowing it to be written on

Pocket – Adding another sheet of plastic to the bag, usually sealed on three sides, to provide additional, separate storage

Perforation – A line of small holes placed on a bag to make it easier to tear off or open…can also be used to make a tamper-evident bag

Header – A separate, sealed area at the top of the bag, often used to allow a sealed bag to have a hang hole

Zipper – A strong, recloseable seal that can be added to many different types of bags

We can! If you have printable artwork, please contact our team and they will help you get a print sample of your label size and artwork at the right price. This will allow you to see how your custom labels will look before printing all labels.

While we will verify the scannability of barcodes in your digital art files prior to submission for production, we do not guarantee end-use scannability of any printed barcodes. We recommend adhering to the minimum barcode size requirements and styles, which require a solid black vector barcode on a white background with a minimum barcode size of 1.2″ x 0.5″. Bar codes used for shrink sleeve labels should be placed vertically for best results.

Polyvinyl chloride (PVC) is a high density film that shrinks at low temperatures. PVC is the easiest film to control during shrinking, and it is also the most commonly used shrink sleeve material. It has excellent shrinkage, sharpness, print quality and a wide range of shrink temperatures and shrink ratios. PVC also has high impact strength for additional weather resistance. This wear-resistant shrink sleeve material is the lowest cost, but also less environmentally friendly than other shrink sleeve materials currently in use.

Polyethylene terephthalate (PETG) is a high density film with a high strength ratio and excellent clarity. While PETG is the most expensive and heat-resistant shrink sleeve material, they are the most abrasion-resistant, have a higher gloss, and have a higher shrinkage ratio. Additionally, PETG is pasteurizable and recyclable, features that are often sought in today’s market.

Polylactide or polylactic acid (PLA) is a biodegradable thermoplastic made from renewable resources. The fact that PLA is biodegradable has increased its popularity in recent years, and in addition to its use as printed shrink sleeve labels, PLA is also used as a loose- filled flexible packaging material.

Expanded Polystyrene (EPS) is a recyclable thermoplastic material. Although EPS is a lightweight material, its light weight, relatively high mechanical strength, and high heat resistance make it an excellent insulator. EPS provides excellent fit product protection.

Use a ruler to measure the size of the label, itself, omitting the backing from your measurements.

Plastic bags, sheeting, and films are available in thicknesses ranging from thin & lightweight to thick & heavy duty. The measurement used for thickness, or gauge, is “mil”, which is about 1/1000th of an inch. Note that mil is a distinct unit of measure and NOT an abbreviation for millimeter. Edco Source offers plastic bags, sheeting, and films in gauges from 0.2 mil to 6 mil.

- Gauges up to 1 mils are the thinnest bags – used for lightweight or temporary needs

- 2-3 mil gauge plastics are widely used for medium duty applications, i.e., food transport

- 4 mil plastics provides heavier protection, i.e., manufacuring packaging for sharp or heavy items

- 6 mil plastics suit heavy-duty applications, i.e., construction tarps and puncture or tear resistance

Follow these steps:

- Measure width (W), depth (D), and height (H) of the container. Note, when ordering bags height = length (L).

- For perfectly square containers, W and D will be the same; for rectangular containers, W is the longer dimension and D is the shorter dimension.

- When ordering bags, add 1″ each to the measured W and D.

- Add a few extra inches to H to account for covering the contents or overhang. Based on the overall size of the container, H may be anywhere from 2″ for small containers to 12″ or more for large containers.

- Example:

Container size: 15″ (W) x 11″ (D) x 20″ (H)

Gusseted bag size: 16″ (W) x 12″ (D) x 24″ (H)

Follow these steps:

- Measure width (W), depth (D), and height (H) of the container. Note, when ordering bags height = length (L).

- For perfectly square containers, W and D will be the same; for rectangular containers, W is the longer dimension and D is the shorter dimension.

- When ordering flat bags, W + D + 2″ = W you should order.

- For H (L), add D + H + a few extra inches to H to account for covering the contents or overhang. Based on the overall size of the container, H may be anywhere from 2″ for small containers to 12″ or more for large containers.

- Example:

Container size: 14″ (W) x 12″ (D) + 20″ (H)

Flat bag size: 26″ (W) x 34″ (H)

Follow these steps:

- Measure the height (H) of the container. Note, when ordering bags height = length.

- Measure the diameter of the container. Then multiply the diameter by 3.14 to get the circumference. Divide the circumference by 2. This will result in the measurement to be used for width (W).

- When ordering bags, add 1″ to the calculated W.

- For H (L), use H (measured in step 1) PLUS diameter (measured in step 2). Add 2″ or more for overhang. 4″-6″ is common for most large trash bins.

- Example:

Container size: 24″ (diameter) x 36″ (H)

Flat bag size: 38″ (W) x 65″ (H)

Follow these steps:

- Measure width (W), depth (D), and height (H) of the pallet. Note, when ordering bags height = length (L).

- For perfectly square pallets, W and D will be the same; for non-square pallets, W is the longer dimension and D is the shorter dimension.

- When ordering pallet covers, add 1″-2″ to the W and D of the pallet.

- H (L) may vary based on the height of items on the pallet. A common guideline is to take the estimated height needed and add 1/2 the depth to it.

- Example:

Pallet size: 30″ (W) x 26″ (D) x 35″ (H)

Gusseted bag size: 32″ x 28″ x 48″

Follow these steps:

- Measure width (W) across the bag from one edge to the other.

- Measure height (H) from the bottom of the zip seal to the bottom of the bag. Do NOT include the zip or the lip between the zip seal and the opening of the bag in this measurement. Note, when ordering bags height = length (L).

- If bags will be used for rigid items close to the size of the bag, add 1/2”-1” to the W and H so items will slip easily into the bag without tearing it.

- Example:

Size of flat, rigid item: 5-1/2″ (W) x 11″ (H)

Flat reclosable bag size: 6″ x 12″

Follow these steps:

- Measure length (L) from the bottom of the slider closure to the bottom of the bag.

- Measure width (W) across the bag from one edge to the other.

- If bags will be used for rigid items close to the size of the bag, add 1/2”-3/4” to the L and W so items will slip easily into the bag without tearing it.

- Example:

Size of flat, rigid item: 5-1/2″ (W) x 11″ (H)

Flat slide seal reclosable bag size: 6″ x 12″

After Purchase Questions

All the printed bags are packed 50pcs or 100pcs one bundle in corrugated carton with wrapping film inside the cartons, with a label marked with bags general information outside the carton. Unless you have specifies otherwise, we reserve the rights to make changes on the carton packs to best accommodate any design, size, and pouch gauge. Please notice us if you can accept our company logos print outside the cartons. If need packed with pallets and stretch film we will notice you ahead, special pack requirements like pack 100pcs with individual bags please notice us ahead.

Depending on the quantity of your order, it will take a few days to a week for the factory to produce. Once your product has been produced and passed the inspection, it will start to be packaged and shipped.

Contact our team for shipping estimates. The final price depends on the delivery location and the weight of the mail package.

The time it takes for your order to arrive depends on the shipping option you choose. You can determine the shipping method and shipping destination according to your needs, so that you can get your label quickly.

For information on ordering shrink sleeves and applying shrink sleeves to cans, visit our Shrink Sleeves information page.

Customers may not combine items to meet minimum quantity requirements. The printing technology we employ does not allow us to fulfill this request. However, our minimum quantities have become more flexible, so please discuss your specific needs with a sales representative.

If you have any questions about your order being defective, please contact us within 30 days of purchase.

Air shipment is available to customers at your own expense. This method of shipment will normally save about 2-3 weeks.

Getting Started Questions

A popular paper carrier bags FAQs question! Pantone is a standardized color matching system which uses a numbering system to identify color shades. When you create your artwork, you will need to choose your pantone colors. Pantone colors can we found on the Pantone Website.

A process print is a print technique which uses 4 standard colors (CMYK) to create a full spectrum of colors. CMYK stands for cyan magenta yellow and black.

We advertise all of our most popular products on our website. There are some obscure products which we are not yet advertising. Please always get in touch with us to see if we have what you are looking for.

Yes we are the factory which has specialized 20 years in packing materials field. If you want professional packing advise, please feel free to contact with us.

Sorry, since all of our products are customized, we don’t have a price list.

Bleed

The printed area on a mechanical layout which extends from 1/8” to _” beyond the visible print area.

Camera Ready Art

Crisp black and white art that is laid out properly in a format that can be directly taken for reproduction.

Chokes and Spreads

Overlap of overprinted images to avoid color or white fringes or borders around image detail. Also referred to as trapping.

CMYK

Acronym for Cyan Blue, Magenta, Yellow, and Black. Printing colors for Process Color reproduction.

Continuous Tone

A screen image which contains gradient tones from black to white.

Dots per Inch

A measure of the resolution of an image. The more dots per inch, thee finer the screen, and the greater the detail. Also referred as “LPI”, lines per inch. DPI or LPI tolerances are dependent on the method of printing along with the finish of the printing surface.

Duotone

A two color halftone reproduction.

Fill In

The undesirable effect of type or copy filling in with ink, usually occurring when reverse copy that is not bold or thick enough.

Flexographic Printing

Method of printing most commonly used to print paper and poly bags, using flexible rubber or photopolymer materials to create the printing plates. Plates are mounted onto cylinders of various diameters for rapid, continuous imprinting.

Font

A complete assortment of letters, numbers, and punctuation marks of a given size and design.

Halftone

The reproduction of a continuous-tone image, through a screening process, which converts the image into dots of various sizes and equal spacing between centers. Generally refers to one-color dot imprints.

Hot Stamping

The process in which foil is directly transferred by means of pressure and heat to a hot stamp printable surface.

Knock Out

Also know as reverse imprint. When printed surface allows for image to reproduce in reverse. Base stock shows through the surrounding inked area.

Moire

The undesirable effect of an unplanned pattern which can be created when two or more screens overlap or overprint with each other at certain incorrect angles.

Negative

Photo film that is a reverse representation of the original copy. All printed areas are clear, and non print areas are black. Negatives are required to make Blue Lines, Color Keys, and Plates.

PMS Colors

Pantone Matching System. An internationally recognized standard color pallet of over 700 colors allowing designers and manufacturers to consistently specify and reproduce an exact color tones.

Pre Printing

Custom print of paper or poly film prior to converting into a bag.

Process Printing

A printing method which uses screen separations of the four basic colors, CMYK. Reproduces vast color spectrum with photographic clarity.

Rotogravure Printing

A method of printing which uses etched metal cylinders and yields a very high quality imprint. “Roto” is generally available for printing from off shore facilities and is used for large quantity print runs of high density frosted bags.

Screen

A uniform measurement of dots in rows or lines per square inch.

Step and Repeat

A printed design in which an element is copied and reproduced over a given area, maintaining equal spacing and direction between elements to create a pattern. Most often identified with simple logo design in repeat pattern on tissue and gift wrap.

Trap

Through the use of “chokes” and “spreads”, overprinting of multiple colors to prevent unprinted areas from showing due potential press movement.

Basis Weight

The weight in pounds of a ream (500 sheets) of paper to a given standard size for that grade; e.g., 500 sheets, 25” x 30”, of 70 pound white kraft shopping bag paper would weigh 70 pounds.

Convert

The process in which plain or pre-printed paper or poly film is mechanically- machined or hand made into a fully finished or partially finished bag.

Draw Closure Bag

Closure for this bag is made from either a choice of poly tape or cotton string. These materials are inserted through a heat sealed fold-over hem at the top of the bag.

Face/Back

The main panel(s) of the bag. Front is considered where the primary design or message appears. Back is utilized for the same imprint or for a secondary imprint. Front and back are differentiated when there are side and bottom gussets. The back is identified where the fold of the bottom gusset occurs.

Flat Bag

Poly bag that has no side or bottom gussets. Can be made with or without a die cut handle.

Fold Over Die Cut Bag

Poly bag in which the material at the top of the bag is folded over to the inside and heat sealed. Fold over reinforcement provides double reinforcement around entire top.

Gauge

The thickness of poly material. Can be measured in mils (English) or microns (metric).

Gusset

The side and/or bottom measurements of a paper or poly bag.

High Density Plastic

A type of plastic typically having a stiffer feel or mil thickness.

Kraft/Brown

A paper containing unbleached wood pulp, brown in color, made by the sulfite process. Also referred to as “Natural Kraft”.

Kraft/White

Brown kraft paper that is put through a bleaching process.

Lamination

A plastic film bonded by heat and pressure to a printed sheet for protection or appearance. Can be supplied as gloss or matte finish.

Low Density Plastic

A type of poly film typically feeling softer and having more gloss and elasticity to it. Most popular as base material for fold over die cuts, soft loop handles, draw closures and litter bags.

M

Abbreviation for a quantity of 1000 units.

Matte Finish

Flat paper finish with out gloss or luster.

Micrometer

A highly sensitive measuring device used to provide the mil thickness of poly bags.

Mil

The English measurement used to describe the thickness of poly. One mil is one one-thousandth of an inch.

Opacity

The property of paper or poly film that minimizes the show-through of printing from the back side of the printed area.

Template

A pre-drawn detailed mechanical layout of a particular bag. Considered a great aid for artists and designers to insure proper art position.