First, the definition of bronzing printing process:

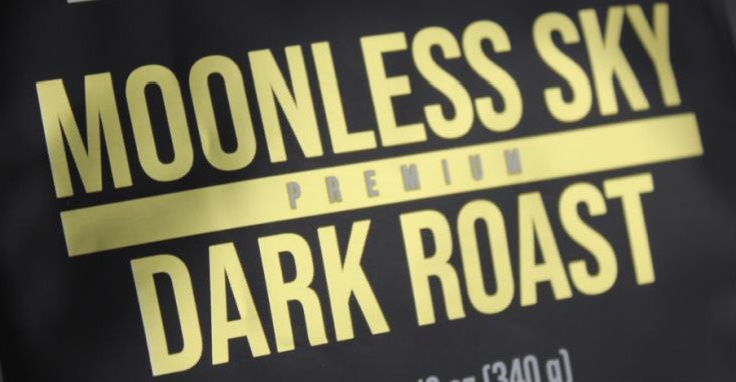

Hot stamping process: a process in which metal foil is transferred to the surface of printed matter or other items by hot pressing to increase the decorative effect.

Cold bronzing process: It is a process of transferring metal foil to the surface of printed matter or other items without heating, only through the force of pressure and bonding and peeling, and has a decorative effect.

Second, the purpose of bronzing:

Make the printing surface have a metal texture pattern of multiple colors at the same time, and also can combine different ironing effects. In addition to the surface decoration function, bronzing also has an important function of anti-counterfeiting.

Third, the advantages and disadvantages of the bronzing process:

1. Advantages:

(1) Hot stamping products on the whole surface, no ink residues;

(2) No unpleasant smell such as ink, no air pollution;

(3) The color pattern is stamped at one time to reduce the loss;

(4) The process is simple, the production management and process actions are smooth, and the product quality is good;

(5) Wide range of processing, suitable for paper, wood, plastic, leather, etc.

2. Disadvantages:

(1) It is not suitable for the substrate with uneven surface of hot stamping, which is pitted or matt;

(2) Metal, glass, ceramics, nylon and other products are generally not suitable for hot stamping unless they are painted or screen printed first;

(3) Matching of pattern color and workpiece background color: during hot stamping, the color of anodized aluminum (gold, silver, copper, inner red, inner blue) has a strong covering power, even if the workpiece background color is black, it can be completely covered; However, when the transfer paper with lighter colors such as white and yellow is used for hot stamping on a black background, the covering effect is not as good as pad printing and screen printing.

Four, bronzing process classification:

1. The hot stamping process is divided into cold hot stamping and hot stamping

2. Hot stamping is divided into: ordinary flat hot stamping, three-dimensional hot stamping (commonly known as embossing and embossing hot stamping), and holographic positioning hot stamping.

Honest Packaging specializes in custom-made kraft paper bags with various bronzing processes. We are better at using packaging to improve product grades and use design to win brand value.