1. Divided according to the laminated form:

single-layer plastic packaging bags and multi-layer laminated plastic packaging bags. Single-layer plastic packaging bags are mainly made of PE plastic film, and there is also heat-sealable BOPP.

Features of single-layer plastic packaging bags:

1) Cheap price

2) Using surface printing process

3) Most of them use benzene-soluble ink

4) Since the ink is on the surface of the printing layer, it is easy to fade compared to the gravure printing composite plastic packaging bag

5) It is mostly used in clothing packaging bags and ordinary food packaging

6) Belongs to low-end packaging

Features of laminated plastic packaging bags:

1) The price is more expensive than single-layer plastic bags

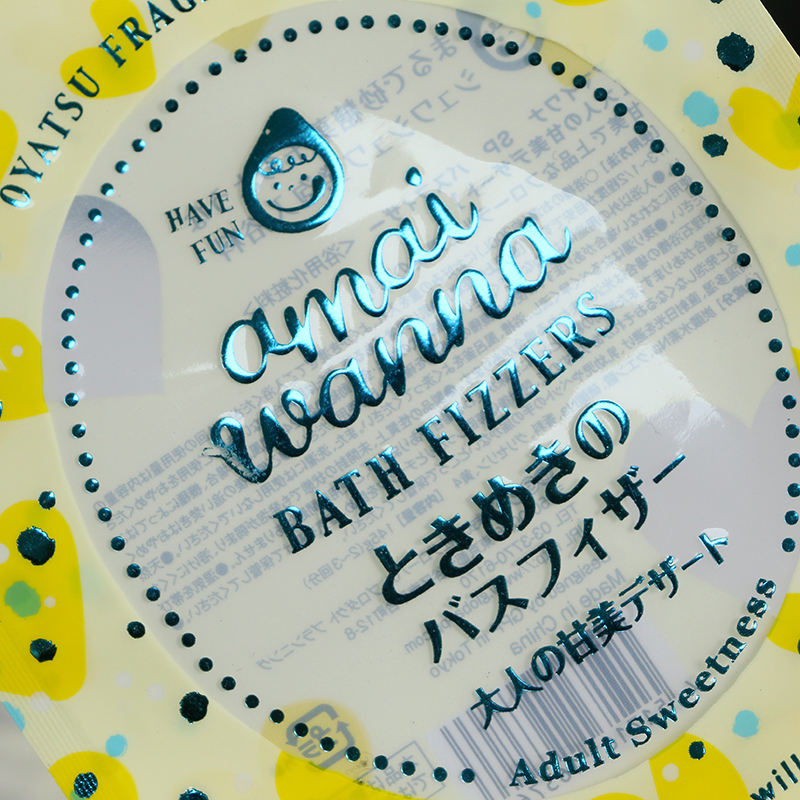

2) Using gravure printing, flexo printing, digital printing, offset printing

3) Most of them use benzene-free and ketone-free inks

4) Due to the use of gravure printing, the printing ink is located on the inner side of the printing layer, and then laminated, so that the color will not be discolored due to problems such as friction and oxidation, and it is much more durable than the surface printing of a single-layer plastic packaging bag

5) Laminated plastic packaging bags have a wide range of applications, such as food industry, chemical industry, daily necessities, etc., due to their exquisite printing and increasing functions, they are used more and more widely

6) Belongs to the middle and high-end packaging

2. according to the packaging function:

general-purpose packaging and special packaging.

For example, packaging in laminated packaging bags: BOPP/PET/PE, BOPP/VMPET/PE, BOPP/PE can be used for most packaging, such as jujube packaging bags, brown sugar packaging bags, condiment packaging bags, dried fruit packaging bags, candy packaging bags, roast duck packaging bags, roast chicken outer packaging bags, drumstick outer packaging bags, etc. Most products can use this kind of packaging material. Other packaging materials can also be customized according to customer requirements.

There are also more special packaging bags:

1) Such as rice packaging bags, millet packaging bags, seed packaging bags, and pet miscellaneous grain packaging bags, if they exceed 2kg, it is recommended to use BOPA/PE or PET/BOPA/PE. BOPA has strong tensile resistance and high Oxygen resistance, and soft texture.

2) High-temperature cooking packaging bags: including cooked food packaging bags such as marinated egg packaging bags, chicken packaging bags, drumstick packaging bags, etc., mostly adopt BOPA/RCPP, because BOPA and RCPP have high temperature resistance, 30 minutes at 121 degrees High temperature, 30 minutes at 131 degrees, no problem. There are also customers who will use BOPA/AL/RCPP to reflect the grade of packaging products.

3) Chemical product packaging bags: including pesticide packaging bags and chemical corrosive product packaging bags, most of them use PET/BOPA/AL/CPP, but because they are compounded with anti-corrosion glue, CPP still has a certain degree of air permeability, and the long-term In use, if the corrosive liquid contacts the anti-corrosion glue through CPP, it may cause delamination.

4) Laundry and chemical products: laundry detergent packaging bags and laundry detergent stand-up pouches. The laundry detergent packaging bags are mainly BOPP/milk white PE, and some customers use BOPP/PET/milk white PE.

3. Classification according to bag shape:

Stand-up packaging bag, stand-up zipper bag, three-side seal zipper bag, stand-up spout bag, shaped bag, ordinary three-side seal, back seal pillow bag, side gusset bag, middle seal bag, etc.

A beautiful package, in addition to being equipped with a suitable bag shape, and its exquisite printing quality, of course, safety and environmental protection are the premise. With the continuous progress and development of the plastic flexible packaging market, plastic packaging bags are not only functional packaging, but people pay more and more attention to the quality and appearance of printing. The advancement of equipment, the proficiency of technology, the rapidity of research and development, the increase of investment, and the accurate grasp of market trends will bring more intense competition to the plastic packaging industry.

Honest Packaging, as a leading supplier in the industry, will continue to provide customers with the best products.